Technology

How Aqua Conditioners Work?

AQUA CONDITIONERS are designed using a unique combination of metals within their alloy core. When water flows through the conditioner, it undergoes turbulence giving rise to a systematic catalytic reaction which breaks down the chemicals and neutralizes the water.The turbulence arising in the water deactivates the adhesive (scaling property) of the hard minerals.

Hard minerals here in this process are converted from large structures into smaller nano colloids reducing the surface tension of the water making it softer. It’s important to note that the mineral content here remains the same. Yet the change in the minerals’ molecular structure causes it to behave differently providing river-like flowy soft water right in your homes.

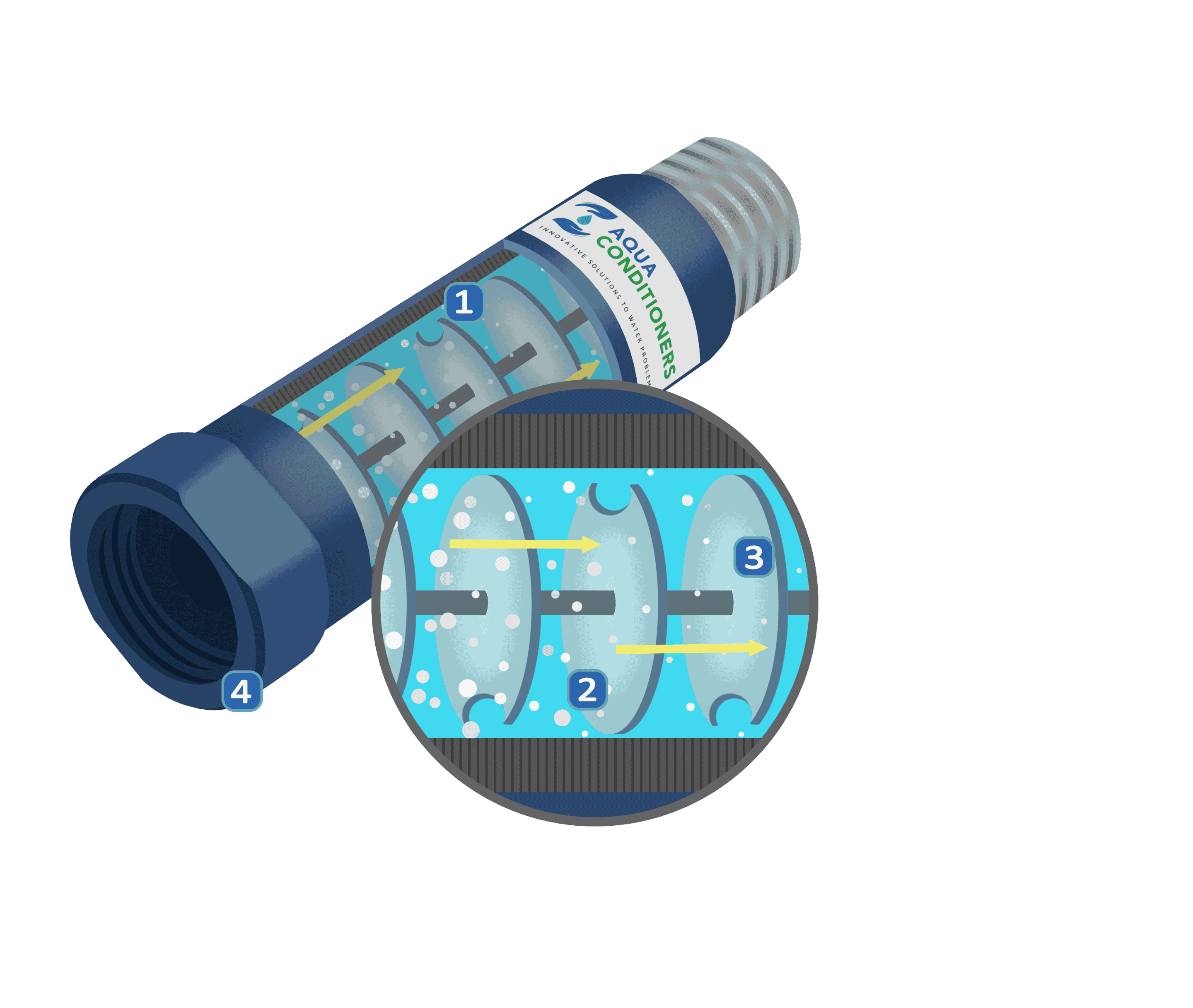

1. Non-sacrificial Alloy Core

Blended in a specialized foundry process, each alloy core is made up of a number of dissimilar metals scientifically selected from the anode and cathode galvanic scale.

The alloy is not a sacrificial anode (i.e., does not need replacement). On contact with water, thousands of intense galvanic electrochemical reactions occur along the length of the alloy core.

2. Catalytic Breakdown & Neutralization

Minerals are attracted to these galvanic sites as they flow through the system. The electrical charge or zeta potential of the minerals in the water is reduced, allowing the minerals to aggregate and form nano-sized colloids, which remain in suspension rather than precipitate on pipes and associated equipment. Minerals with high zeta potential are electrically stabilised, repelling each other and precipitating on pipes and equipment. The electro-physical changes in the minerals neutralize their scale producing properties. The result is that the previously ‘hard’ minerals are changed from being large Calcite molecules into inactive, microscopic Aragonite particles.

3. Deactivation of Scaling Properties

The scale and residue that usually sticks and causes scale buildup in pipes, valves and other surfaces are prevented from forming. It changes hard minerals in the water to inactive microscopic particles. These inactive mineral particles stay suspended in the water (much like minerals are suspended in milk) and flow freely, without sticking to surfaces. Most importantly, unlike hard water minerals, if the inactive mineral particles occasionally drop out of suspension, they can easily be washed or wiped away without the use of chemicals.

4. Premium Industrial Grade Housing

With a 5 year warranty , our products are made from premium grade stainless steel 316. Making our conditioners eco friendly, long lasting, corrosion and rust free.

Safety and Installation

What is the Science Behind an Aqua Conditioners System?

The Physics:

-

Blended in a specialised foundry process, each alloy core is made up of a number of dissimilar metals scientifically selected from the anode and cathode galvanic scale. The alloy is not a sacrificial anode (i.e. does not need replacement).

-

On contact with water thousands of intense galvanic electrochemical reactions occur along the length of the alloy core.

- Minerals are attracted to these galvanic sites as they flow through the system.

- The electrical charge or zeta potential of the minerals in the water is reduced allowing the minerals to aggregate and form nano sized colloids which remain in suspension rather than precipitate on pipes and associated equipment.

The Chemistry:

-

Each alloy core has been designed and engineered for a specific flow range.

- Each core has offset discs so that there is no direct route for the water to travel. There is a definite water alloy contact.

- Water velocity is increased as water is squeezed through the disc apertures and on through the chambers along the length of the core.

- High and low pressure areas are developed either side of each disc. Extreme turbulence is generated in each chamber along the length of the core.

- The increase in water velocity and turbulence combine and create a mechanical washing action which prevents minerals building up on the core.

Still wondering how we make your water River-Like soft?

Here’s the secret of an Aqua Conditioners’ system:

-

Over 60 % reduced particle size – It makes water less dense !

- Over 90% reduced mineral charge – It makes the elements glide !

- Resulting in reduced surface tension – It makes your water thinner and softer than ever before !

CONDITIONER CARE

We recommend cleaning your Conditioner once a year

After a year of continual use the surface of the alloy core may be coated with a layer of sediments or contaminants. This could interfere with the expected results and needs to be cleaned. Check out our guidelines on Conditioner Care

Are you looking for a whole house solution? We’ve got you covered.

Aqua Conditioners has solutions for all sorts of home applications. Be it a shower or tap, bathroom or kitchen in a flat or an independent home or villa.

Check out our entire home range!